Safety is one of the driving forces of our Protective and Marine Coatings innovations. That’s why we’re #PPGProud to share the story of an innovative product and of the team that brought it to the market: meet PITT-CHAR NX, a product that is already causing a stir thanks to the innovation, perseverance and professionalism of our Hydrocarbon Passive Fire Protection (HPFP) team.

The Diverse Team Behind the Success

Giuseppe “Pino” De Luca is the key account manager Europe for Hydrocarbon Passive Fire Protection and is based in Italy. Having expertise in this field, he meets with customers from the industrial sector and discusses the best solutions for their needs.

This is not only a job for me, but rather a passion I’ve held for twenty years.

Pictured from left: Luciano Carubelli (PPG), Alessio Trisolino (Donelli Group), Fausto Vaglietti (Donelli Group), Giuseppe “Pino” De Luca (PPG)

He is proud to have been working alongside a diverse team for a year now:

-

Peter Scott (business development manager, EMEA hydrocarbon PFP)

-

Mark Arnott (PITT-CHAR NX field technical support)

-

Luciano Carubelli (PITT-CHAR NX account manager North-West Italy)

-

Paolo Rossa (PITT-CHAR NX technical support manager Italy)

Each one of us has brought their own experience and expertise to the service of the customer, and our joint cooperation has been a success.

Such cooperation has confirmed, once again, that diversity among colleagues can only be an advantage for PPG and our customers.

Saving Time, Money, Assets and Lives with Amazing Technology

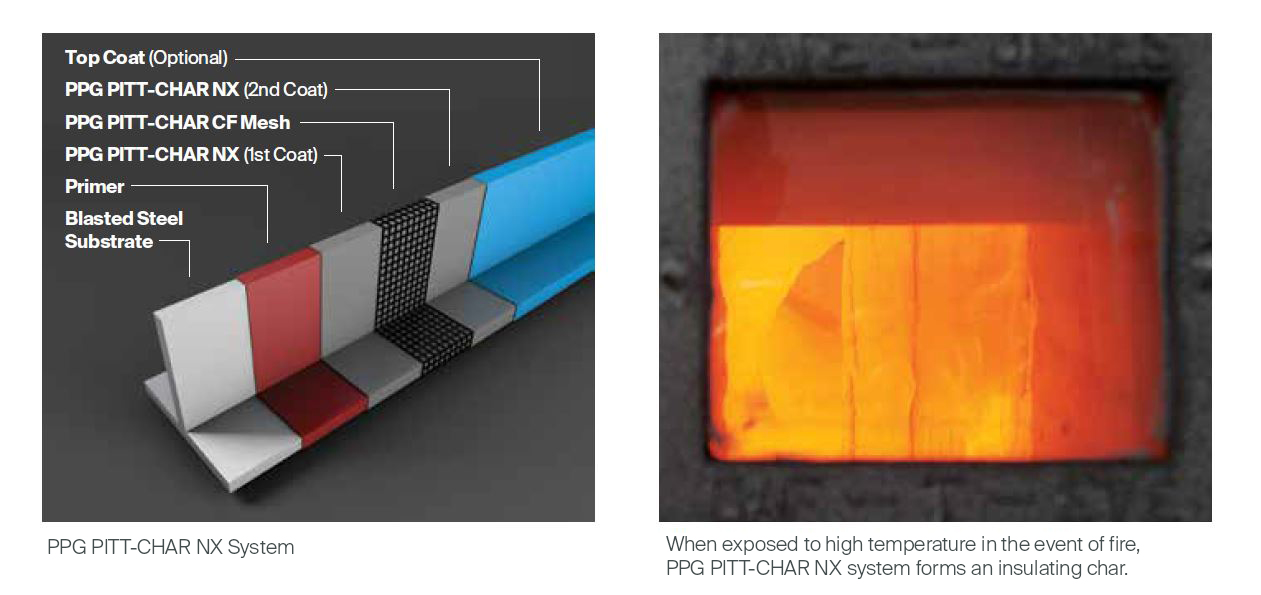

Recently, the team has been working with PITT-CHAR NX. The product is an epoxy intumescent paint that protects steel structures from severe fires. In onshore or offshore facilities, these can occur as hydrocarbon fires, jet fires or combination of both. Why are products like PITT-CHAR NX so crucial?

In a jet fire, ambient temperatures can reach 1,300 °C in just five minutes. This creates an incredible thermal shock and structural stability can be at risk. In this scenario, PITT-CHAR NX ‘swells’ to form an insulating layer that acts as a barrier between the fire and the structure.

This permits more time for people to escape and for firefighters to extinguish the fire to try to avoid structure collapses.

It represents a major advance in the protection of assets in high-risk environments from all hydrocarbon hazards. Not only is it the safest, thinnest, lightest and most flexible product of its kind on the market, but it’s faster to apply and helps reduce costs for customers.

Getting an Important Client On Board

The Donelli Group is the largest contractor in Italy of hydrocarbon passive fire protection and one of the most important contractors and customers in Europe.

My task was to encourage them to try PITT-CHAR NX so they could feel the difference for themselves.

Giuseppe and his HPFP team started preparing in February for training in March. Because of its specifics, they had to train the customer to use and apply the product properly. Then suddenly, it had to be postponed to June because of the pandemic.

Despite such difficult times, we had not given up. Instead, we turned what presented as a disaster into an advantage. Guided by

The PPG Way, we knew the key was to ‘partner with the customer to create mutual value’!

Careful Planning and Preparation

The team managed to make the most of the slow business period together with the customer and dedicate time, effort and people to this important training.

Just two days ahead of the training, I visited the client twice to make sure everything was ready. It would normally take around 40 days to organize such events!

Thanks to the careful planning and preparation of the team, Giuseppe and his HPFP team were able to instruct 12 applicators on how to heat up the material to the proper temperature, how to mix it, and what the correct application techniques are. After the application, they explained how to smooth it and how to make physical controls.

For the proper experience, the applicators learned to use an extremely sophisticated plural pump for large projects, but also how to apply the product in small areas, for touch-ups and repairs.

Creating Mutual Value

The customer had been skeptical about the final applied density PPG had anticipated for PITT-CHAR NX. As Giuseppe explains, density is an important quality: as the higher the final density, the more product is used for its application, which would make the product less attractive to customers. So, it plays a major role in the success of such products…

But once the application stage of the training was complete, the results were clear.

We are

#PPGProud of our strong innovations and keeping our promises with our products and honored to be viewed as reliable professionals and a trusted partner.